Fred C Dimock

Global Services

Thermal Process Consulting

Assisting thermal industries with process optimization and problem solving.

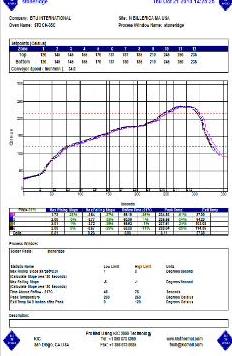

We focus on continuous furnace processes and furnace profiling.

SMT solder reflow and void mitigation

Glass to metal seals and other thermal processes

What we do!

I CAN HELP YOU FIND SOLUTIONS TO THERMAL PROCESS ISSUES !

Atmospheres include Air, Nitrogen, Hydrogen, Forming Gas, and Vacuum

Surface mount reflow and void mitigation

Fred is the author of numerous papers that have been distributed world-wide on lead-free processing, vacuum reflow, and surface mount cost reduction. Many have been translated into German, Chinese, and Spanish. He is a highly rated SMTA instructor and considered by many to be the world expert at surface mount profiling and reflow oven recipe attainment. He has also conducted numerous vacuum reflow workshops at ACI Technology in Philadelphia, is recognized as a Distinguished Speaker at SMTA Guadalajara and a principal speaker in the SMTA Jump Start program where he covers the fundamentals of solder reflow.

Glass-to-metal seals

Fred is the former Senior Market Specialist for glass frits at Corning Incorporated where he assisted customers worldwide with process assistance for CRT, glass-to-metal sealing, and electronic assembly. Due to his vast knowledge of glass and glass processes he has continued to be in demand to assist in glass-to-metal seal processing.

High temperature firing

While at Sylvania, Fred was involved with isostatic pressure and the firing of translucent polycrystalline alumina that required temperatures approaching 1900 C in hydrogen. He jokes that low temperature firing during those days was 1500 C in air. He successfully specified and installed multiple large furnaces (including the design of molybdenum alloy kiln furniture) with a project cost of $5.4M.

LTCC Firing & Direct Bond Copper

After joining BTU, Fred assisted customers worldwide with process and furnace control guidance in LTCC and one, two, and three step Direct Bond Copper production.

Manufacturing Excellence

As Shop Operations and Material Manager at General Electric, Fred designed and implemented a quality control system that facilitated decreased inventory, increased productivity, and lowered customer returns while simultaneously meeting increased customer quality requirements.

Other thermal processes

Lead free solder, sintering, wafer bump reflow, annealing, thick film firing, poly crystalline alumina sintering, isostatic pressing, and furnace brazing.

Additional experience in ceramic extrusion and power compacting